Ndị injinia na-arụ ọrụ kwesịrị ịṅa ntị na njirimara nke ihe dị iche iche n'oge nhazi. Ndị injinia dị elu nke Cheng Shuo nwere amamihe ụlọ ọrụ bara ụba gbasara nhazi akụrụngwa.

Edemede a ga-ewebata gị njirimara na ojiji nke akara ule aluminom emeziri nke ndị injinia Cheng Shuo Hardware na-ejikarị.

Njirimara na ojiji nke akara ule aluminom edoziri

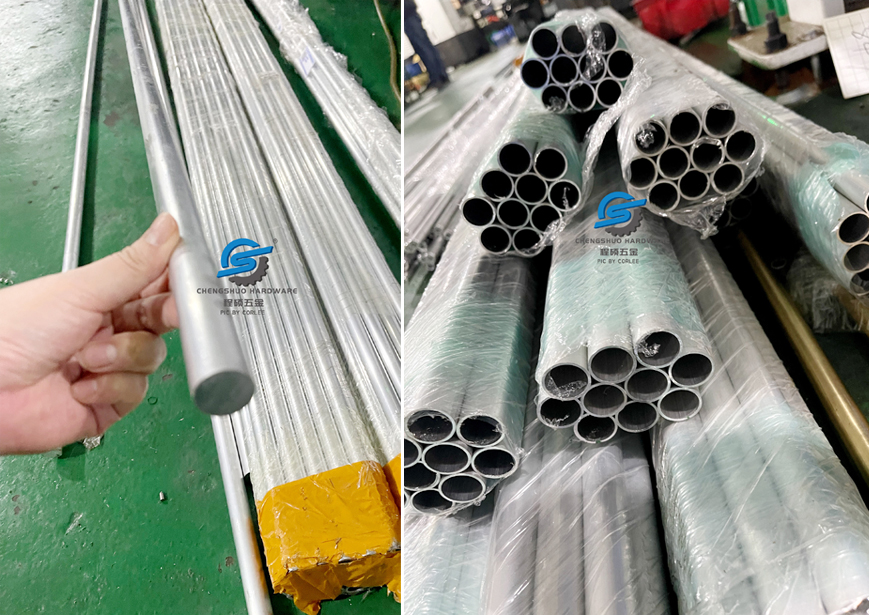

Aluminom dị ọcha

Akara akara ndị a na-ejikarị gụnyere 1A99, 1A97, 1A93, 1A90, 1A85, wdg. Aluminom dị ọcha maka ụlọ ọrụ mmepụta ihe, ihe dị n'ime aluminom nwere ike ịdị elu dị ka 99.99% (ọnụọgụ oke). A na-ejikarị eme nchọpụta sayensị, ụlọ ọrụ kemịkalụ na ụfọdụ ebumnuche pụrụ iche, dị ka imepụta igbe igbe electrolytic capacitor dị iche iche, igbe na-eguzogide acid, wdg Ngwaahịa gụnyere efere, ibe, tubes, igbe, wdg.

Ụlọ ọrụ dị ọcha Aluminom

1060,1050A,1035,1200,8A06,1A30,1100

Aluminom dị ọchanwere nnukwu plasticity, nguzogide corrosion, eletriki eletriki na ọkụ ọkụ, ma ike dị ala, enweghị ike ime ka ọgwụgwọ okpomọkụ sie ike, na usoro adịghị mma; ọ nwere ike ịbụ gas welded, hydrogen atom welded na kọntaktị welded, adịghị mfe agịga weld, na nwere ike mfe idi iche iche nrụgide nhazi na Deep ịbịaru na ekwe. A na-eji ya ka ọ ghara ibu ibu mana ọ chọrọ njirimara ụfọdụ. Dị ka structural components na elu plasticity, elu corrosion eguzogide ma ọ bụ eletriki conductivity na thermal conductivity, dị ka gaskets, capacitors, tube iche cover, electric wires, waya cores, wdg 1A30 bụ tumadi eji maka dị ọcha aluminum diaphragms na aerospace ụlọ ọrụ na ngwá agha. ụlọ ọrụ. Mpekere 1100 na ibe dị mma maka imepụta ngwaahịa dị omimi dị omimi.

Ngwakọta mgbochi nchara

5A02, 5A03 nwere elu ike karịa 3A21, elu plasticity na corrosion iguzogide, enweghị ike ike site okpomọkụ ọgwụgwọ, na nwere ezi weldability (The weldability nke 5A03 dị mma karịa nke 5A02), na workability dị mma na oyi na-atụ na-arụ ọrụ siri ike steeti, na processability bụ ogbenye na annealed ala, na ọ nwere ike polished. Akụkụ ịgbado ọkụ nke ọkara, akụkụ oyi steepụ na arịa, akụkụ skeleton, mkpanaka ịgbado ọkụ, rivets, wdg eji arụ ọrụ n'okpuru mmiri mmiri.

Duralumin

2A16, 2A17

Okpomọkụ na-eguzogide duralumin nwere obere ike na ụlọ okpomọkụ mana ike na-akpụ akpụ na nnukwu okpomọkụ. Ọ nwere nnukwu plasticity na steeti na-ekpo ọkụ ma nwee ike wusie ike site na ọgwụgwọ okpomọkụ. 2A16 nwere ezigbo ịgbado ọkụ ntụpọ, ịgbado ọkụ onuete na arc ịgbado ọkụ arụmọrụ, ala corrosion eguzogide na ezi processability. A na-eji ya maka akụkụ ndị na-arụ ọrụ na 250 ~ 350C, dị ka axial compressor blades na discs; A na-eji efere eme ihe na ụlọ okpomọkụ ma ọ bụ akụkụ welded na-arụ ọrụ na okpomọkụ dị elu, dị ka arịa, ụlọ ikuku ikuku, wdg. 2A17 enweghị ike iji ya mee ihe maka ịgbado ọkụ ma jiri ya mee ihe na stampụ na-achọ ike dị elu.

Aluminom akpara akpa

2A50

Aluminom siri ike dị elu nwere nnukwu plasticity na steeti ọkụ, ọ dị mfe ịmepụta na stampụ, a pụkwara ime ka ọ dịkwuo ike site na ọgwụgwọ okpomọkụ; nwere ezigbo usoro arụmọrụ na ezigbo nguzogide corrosion, ma ọ nwere ọdịdị nke corrosion intergranular; processability na ntụpọ ịgbado ọkụ na onuete ịgbado ọkụ The arụmọrụ nke kọntaktị ịgbado ọkụ dị mma, ma arụmọrụ nke electric ịgbado ọkụ na gas ịgbado ọkụ adịghị mma. Maka forgings na stamping nwere ụdị mgbagwoju anya na ike ọkara.

6061, 6063

A na-eji 6061 maka akụkụ nwere ike ọkara (Rm≥270MPa), na-arụ ọrụ na nso nke -70 ~ + 50℃ma na-achọ nguzogide corrosion ruru eru na mmiri mmiri na mgbasa ozi mmiri (dị ka ụgbọ elu helikopta, igbe wiil ụgbọ mmiri)

A na-eji 6063 maka akụkụ ndị na-achọghị ike dị elu (Rm≥200MPa), ezigbo nguzogide corrosion, elu ịchọ mma mara mma, na-arụ ọrụ na -70-+50℃. Enwere ike iji ya chọọ ọdụ ụgbọ elu mma ma na-ejikarị ya na windo windo, oghere ọnụ ụzọ, igwe mbuli elu, ngwá ụlọ, wdg na ụlọ obodo. Mgbe ọgwụgwọ ọkụ eletrik pụrụ iche gasịrị, alloy nwere ihe nrụpụta eletrik dị elu ma jiri ya mee ihe na ụlọ ọrụ eletrik.

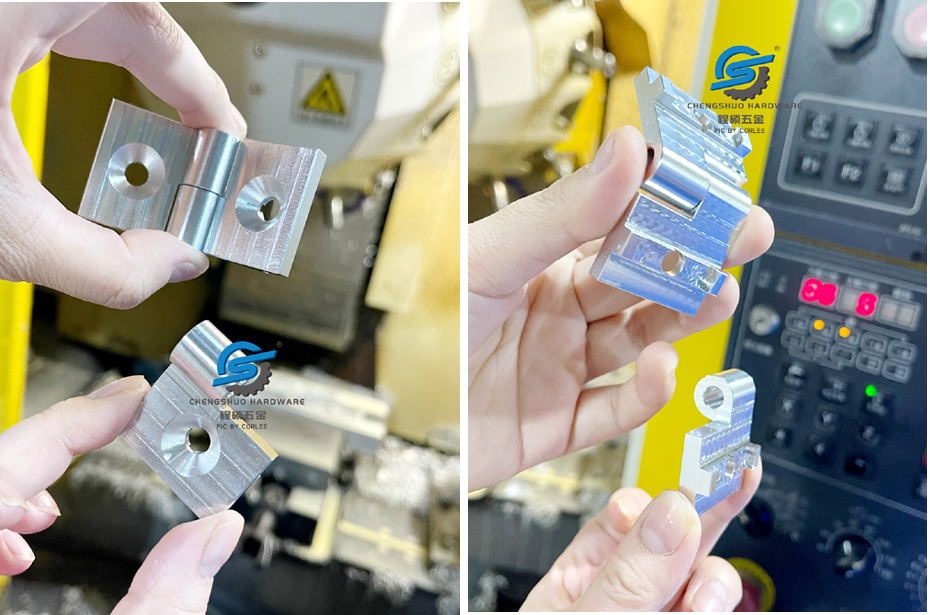

Ihe ndị a na-ahụkarị nke 6061 na 6063 bụ ike ọkara na ọmarịcha weldability. Ọ nwere ezigbo nguzogide corrosion na oyi na-arụ ọrụ ma bụrụ ihe a na-ejikarị eme ihe.

Ọtụtụ ọrụ arụchara na Chengshuo emere site na aluminom 6061. Aluminom Machining Parts bụ ngwaahịa nkịtị na ngwaike Chengshuo, mgbe ịmechara machining anyị nwekwara ike ịgbawa ájá & anodizing.

Super Duralumin

7A03 superduraluminum rivet alloy nwere ike wusie ike site na ọgwụgwọ okpomọkụ, nwere ike ịkwa akwa, nguzogide corrosion na-anabata na nhazi usoro, ọ bụghịkwa njedebe site na oge ọgwụgwọ okpomọkụ n'oge riveting. Rivets maka ihe arụrụ arụ. Mgbe okpomọkụ na-arụ ọrụ adịghị elu karịa 125℃, enwere ike iji ya dochie anya 2A10 rivet alloy.

Aluminom pụrụ iche

4A01 bụ obere alloy aluminom-silicon alloy nke nwere ọdịnaya silicon nke 5%. Njirimara akụrụngwa ya adịghị elu, mana nguzogide corrosion ya dị oke elu; ọ nwere ezigbo nhazi nhazi nrụgide. Kwesịrị ekwesị maka ịme mkpanaka ịgbado ọkụ na mkpara ịgbado ọkụ, eji eme ihe maka ịgbado ngwaahịa aluminom alloy.

Oge nzipu: Jun-05-2024