Iji mejuputa oru ngo metal ngwaike, ndị injinia anyị ga-eji nlezianya họrọ usoro maka itinye ngwaahịa dị iche iche.

Usoro nhazi a na-ahụkarị maka ngwaahịa ngwaike ugbu a gụnyere:

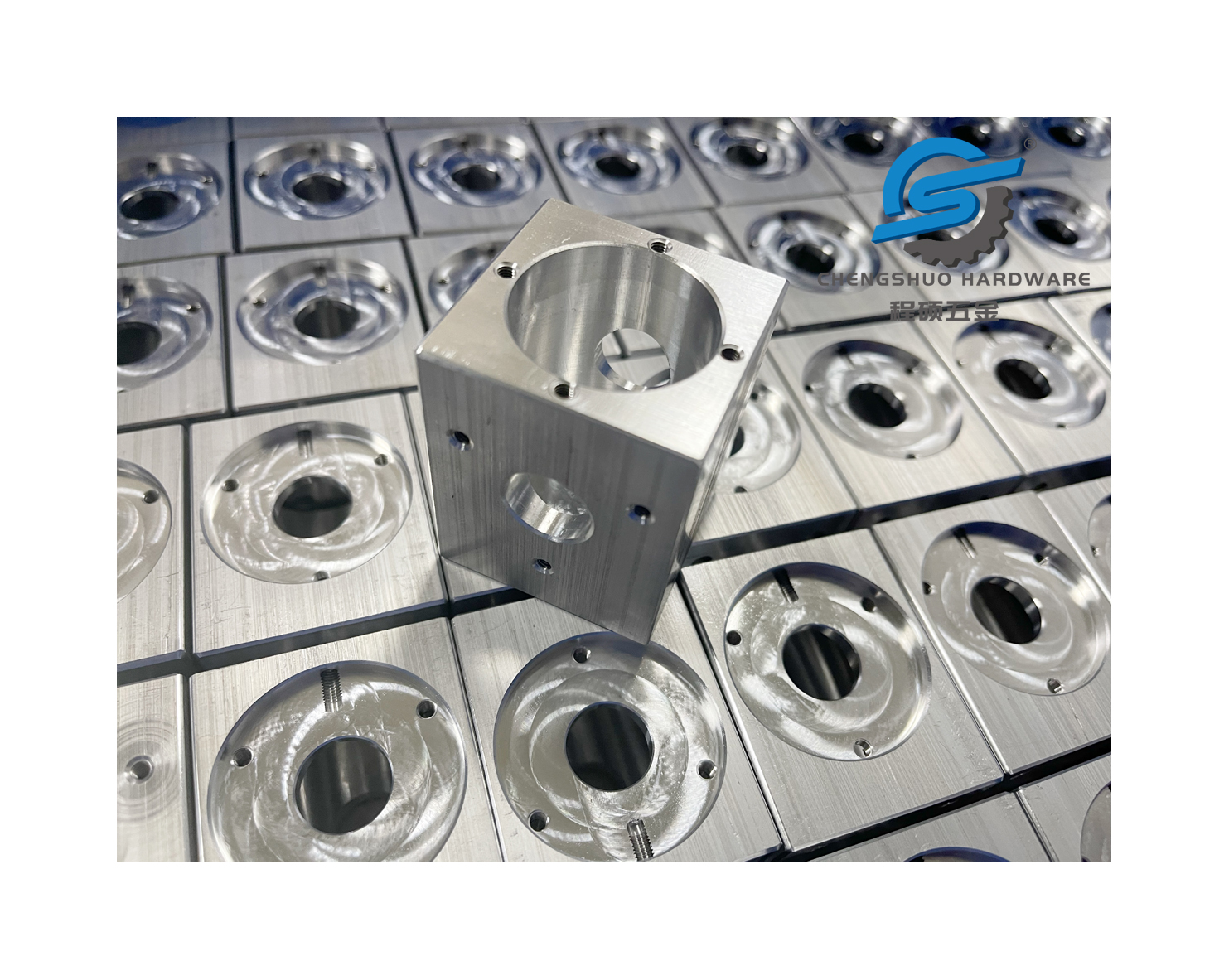

1. CNC igwe

CNC ntụgharị, igwe-egwe ọka, ịkụ ọkpọ, CNC cnhazi nhazi na-ezo aka n'usoro nke ịkpụ otu ọrụ n'ime ọdịdị na nha achọrọ site na ngwá ọrụ ịkpụ. Usoro igbuchasị ihe ndị a na-ahụkarị gụnyere ntụgharị, igwe igwe, igwu mmiri, wdg.

N'ime ha, ntụgharị bụ iji ngwá ọrụ ịkpụ na lathe iji hazie mpempe ọrụ na-atụgharị, nke nwere ike ịmepụta akụkụ dị iche iche nke dayameta, ogologo na ọdịdị osisi;

Egwe ọka bụ iji ngwaọrụ ịkpụ n'igwe igwe igwe na-atụgharị na ịkwagharị iberibe ọrụ, nke nwere ike ịmepụta ụdị dị iche iche dị larịị na convex concave elu nke akụkụ;

Ịkwọ ụgbọ mmiri bụ iji ngwá ọrụ ịkpụ n'elu igwe na-egwupụta ihe na-egwupụta oghere n'ime iberibe ọrụ, nke nwere ike ịmepụta oghere nke dayameta na omimi dị iche iche.

Chengshuo ejirila ụlọ ọrụ CNC nke anyị, nke nwere ike ịnye ọrụ nkwụsịtụ maka ngwaahịa dị elu ahaziri nke ọma nwere ngwa dị iche iche.

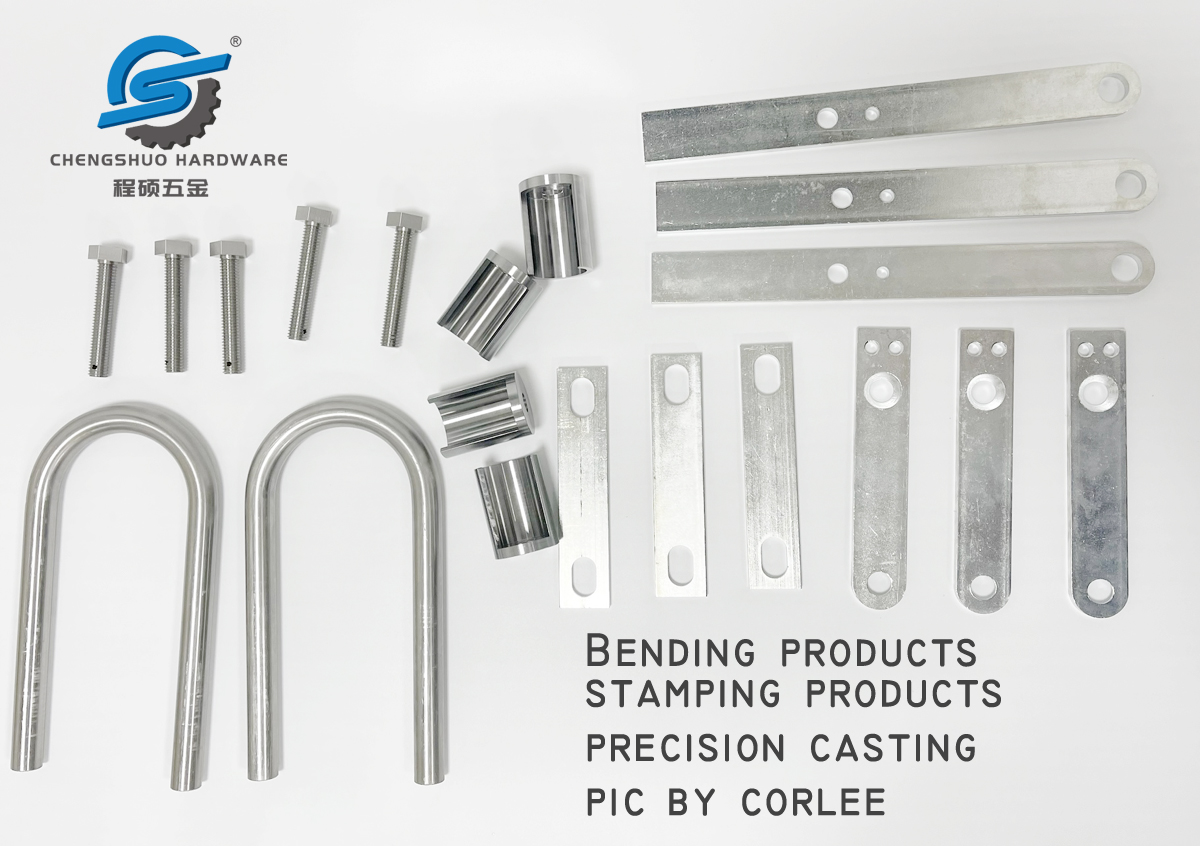

2. Stamping nhazi - Stamping center

Nhazi stamping na-ezo aka na usoro nke stamping metal ibé n'ime udi a chọrọ site stamping ebu. Usoro stamping nkịtị na-agụnye ịcha, ịkụ ọkpọ, na-ehulata, wdg N'ime ha, ịcha bụ ịkpụ mpempe akwụkwọ metal dị ka ụfọdụ nha iji nweta nha achọrọ nke akụkụ dị larịị. Punching bụ iji ihe na-akpụ akpụ na igwe ọkpọ ọkpọ na-akụ mpempe akwụkwọ ígwè ahụ, nke nwere ike nweta ụdị dị iche iche na oghere nke oghere; Ehulata bụ iji igwe na-ehulata na-ehulata ibé ígwè, na-akpata ụdị dị iche iche na akụkụ akụkụ.

Stamping die bụ ngwá ọrụ pụrụ iche nke a na-eji eme ihe n'ịhazi stamping oyi iji hazie ihe (ígwè ma ọ bụ ndị na-abụghị ígwè) n'ime akụkụ (ma ọ bụ ngwaahịa emechachara), nke a na-akpọ oyi stamping die (nke a na-akpọkarị oyi stamping die)

Nkewa a na-ahụkarị nke stamping ebu:

(1) Otu usoro ebu bụ ebu nke na-emecha naanị otu usoro stampụ n'otu strok nke pịa.

(2) Ihe mejupụtara ihe mejupụtara nwere naanị otu ebe ọrụ, na n'otu strok nke pịa, ọ bụ ihe ebu na-emecha usoro stamping abụọ ma ọ bụ karịa n'otu oge n'otu ebe ọrụ.

(3) Ọnwụ na-aga n'ihu (nke a makwaara dị ka anwụ na-aga n'ihu) nwere ebe ọrụ abụọ ma ọ bụ karịa na ntụziaka nke nri akụrụngwa. Ọ bụ ihe ebu na-emecha usoro stampụ abụọ ma ọ bụ karịa na ọdụ ọrụ dị iche iche n'otu strok nke akwụkwọ akụkọ.

(4) The nyefe ebu na-ejikọta àgwà nke otu usoro ebu na-aga n'ihu ebu. Site n'iji usoro mbufe ogwe aka robotik, enwere ike ibufe ngwaahịa ngwa ngwa n'ime ụdị ahụ, na-eme ka nrụpụta nrụpụta dị ukwuu, ibelata ọnụ ahịa mmepụta, na-echekwa ọnụ ahịa ihe, yana hụ na ịdị mma kwụsiri ike na ntụkwasị obi.

3. Nhazi ịgbado ọkụ

Nhazi ịgbado ọkụ na-ezo aka na usoro ijikọ ihe igwe abụọ ma ọ bụ karịa site na kpo oku, agbaze, ma ọ bụ nrụgide. Usoro ịgbado ọkụ ndị a na-ahụkarị gụnyere ịgbado ọkụ arc, ịgbado ọkụ fluorine, ịgbado ọkụ gas, wdg. N'ime ha, ịgbado ọkụ arc na-eji ọkụ arc nke igwe ịgbado ọkụ na-agbaze ma jikọta ihe igwe ọnụ; amonia arc welding na-eji okpomọkụ nke amonia arc na-emepụta n'okpuru nchebe nke gas na-ekpuchi ya iji gbazee ma jikọta ihe ígwè ọnụ; ịgbado ọkụ gas na-eji ọkụ ọkụ na-emepụta site na combustion nke gas agbaze na jikọọ ihe metal ọnụ.

4. Nhazi nhazi - ebe etiti na-ehulata

Usoro ịgbagọ na-ezo aka na usoro nke na-ehulata ihe igwe n'ime ọdịdị a chọrọ site na igwe na-ehulata. Usoro ịgbagọ nkịtị na-agụnye V-ehulata, U-ehulata, Z-ehulata, wdg N'ime ha, V-ekwe ekwe na-ezo aka ekwe na metal mpempe akwụkwọ na a akụkụ na-etolite a V-ediri udi; Ihu ihu U na-ezo aka na-ehulata mpempe akwụkwọ ígwè ahụ n'otu akụkụ iji mepụta udi U; Z-ehulata bụ usoro ehulata mpempe ígwè n'otu akụkụ iji mepụta ụdị Z

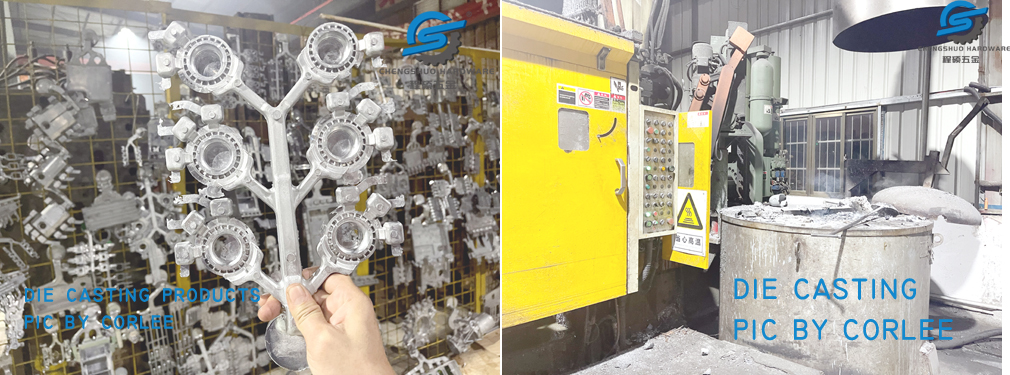

5. Nhazi nkedo anwụ - Ebe nkedo anwụ anwụ

A na-ejikarị eme ngwaahịa ngwaike siri ike. Nkedo anwụ bụ mbiri maka nkedo nrụgide. Ọ bụ usoro iji mejupụta oghere nke ihe nkedo anwụ anwụ na mmiri mmiri ma ọ bụ ọkara mmiri mmiri na nrụgide dị elu ma na-agbake ngwa ngwa n'okpuru nrụgide iji nweta nkedo. A na-akpọ ihe nkedo anwụ anwụ ejiri mee ihe nkedo anwụ anwụ.

6. Nhazi ịcha waya

Ngwaike Chengshuo nwere akụrụngwa igbutu waya nke ya. Ịcha ahịrị bụ mbiri maka ịkpụ ahịrị, na-ezo aka na usoro nhazi. Ọ mepụtara na ndabere nke eletriki mwepu perforation na akpụ nhazi. Ọ bụ usoro nhazi nke na-eji wires metal na-akpụ akpụ (waya molybdenum, waya ọla kọpa, ma ọ bụ waya alloy) dị ka wires electrode, ma na-ebute okpomọkụ dị elu site na mgbapụta ọkụ eletrik n'etiti wires electrode na workpiece, na-eme ka metal ahụ gbazee ma ọ bụ vaporize, na-akpụ. na-egbutu seams, wee si otú a na-egbutu akụkụ ahụ.

Mgbe nhazi dị iche iche gasịrị, ngwaahịa ahụ na-enweta ọgwụgwọ elu dị iche iche.

Ọgwụgwọ n'elu na-ezo aka na usoro nhicha elu, iwepụ nchara, mgbochi corrosion, spraying na ọgwụgwọ ndị ọzọ maka ihe ngwaike. Ngwọta ndị a na-ahụkarị na-agụnye pickling, electroplating, spraying, wdg N'ime ha, ịsacha acid bụ iji ngwọta acidic na-emebi ma hichaa elu nke ngwaike ngwaike, wepụ oxides na unyi n'elu. Electroplating bụ ojiji nke electrolysis na-edebe metal ion n'elu ngwaike components na-etolite a ihe nkiri na-echebe ma melite ha corrosion iguzogide; Ịfesa bụ iji ngwa ịgbasa agba na-efesa agba n'otu n'otu n'elu ihe ngwaike, na-akpụ ihe nkiri na-echebe iji kwalite mma ha na nguzogide ihu igwe.

Oge nzipu: Dec-13-2023