Akụkụ ọla kọpa CNC machining nwere ike inwe ezi formability na ma oyi na-ekpo ọkụ machining Filiks. Na mgbakwunye, Injinias naChengshuo haveọgaranya ahụmahụsna ọgwụgwọ elu maka ngwaahịa na ngwa nhazi ọla.

N'ikwu okwu n'ozuzu, ọtụtụ ihe na akụkụ ọla nwere ezigbo igwe, ductility, na ike mmetụta, yana nnukwu okpomọkụ conductivity, conductivity, corrosion resistance, and wear resistance.

Nzọụkwụ maka ịrụ ọrụ Brass/Copper CNC

1. Họrọ nke ziri eziọla /ọkwa ọla kọpa

Tupu nhazi ọla kọpa CNC, ga-ahọrọrịrị ọkwa ọla kọpa ziri ezi nke kachasị dabara gịngwaahịa' ngwa. Dịka ọmụmaatụ, ịhọrọ ọla kọpa dị ọcha iji rụpụta akụkụ igwe adịghị mma ma dị oke ọnụ. Ya mere, ọ dị mfe ịkpụ ọla kọpa nwere ezigbo igwe ma bụrụ ihe kachasị mma. Tụkwasị na nke ahụ, ha nwekwara uru bara uru.Mkpalelee arụmọrụ achọrọ nkeọla /akụkụ ọla kọpa ịhọrọ ọkwa ọla kọpa ziri ezi.

2. Nhazi maka nrụpụta (DFM)

Tupu nhaziọla /ọla kọpa,Ndị injinia Chengshuo chọrọghọtakwa ihe ndị chọrọ imewe na nkọwapụta. Nke a ga-enyere aka nweta ọrụ achọrọ maka ọla kọpaọla kọpaakụkụ. Iwu nke isi mkpịsị aka bụ iji na idowe ọkpụrụkpụ mgbidi nke 0.5 millimeters iji rụpụta ọla kọpa mara mma nke ukwuu./ọlaakụkụ.

3.Tọọ ọnụego nri kwesịrị ekwesị

Ọnụọgụ ndepụta bụ ọsọ nke ihe eji egbutu ihe meshes na mpempe ọrụ. A ghaghị ịtọ ọnụego nri ziri ezi tupu ịhazi akụkụ ọla kọpa, ebe ọ na-emetụta àgwà, ndụ ọrụ, na ire ụtọ nke akụkụ ọla kọpa. Na mgbakwunye, ọla kọpa/ọlanwere ngwa ngwa thermal conductivity, na ọnụ ọgụgụ nri dị elu ga-abawanye ngwá ọrụ.

4. Họrọ ngwá ọrụ ziri ezi

Ọtụtụ ọla kọpa ihe nwere dị iche iche processability na anwụ ngwa ngwa. Ya mere, ọ dịkwa mkpa ịhọrọ ngwá ọrụ kwesịrị ekwesị maka nhazi akụkụ ọla kọpa, nke na-enyere aka igbochi nsogbu ndị dị ka iyi ngwá ọrụ na mgbochi mgbawa.

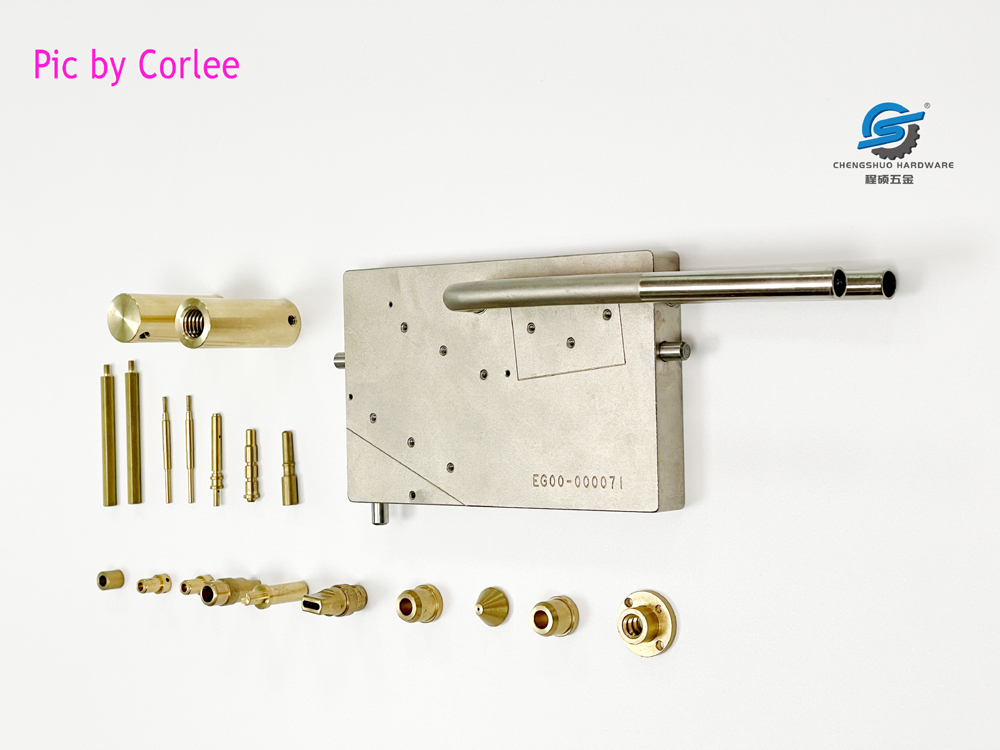

Ngwọta biputere nke ngwaahịa ọla kọpa ejiri CNC emechara

Ụzọ ọgwụgwọ elu ndị a na-ahụkarị maka ọla kọpa/ọlaNgwaahịa mgbe igwe CNC gachara gụnyere:

1. Electrolytic polishing

Electrolytic polishing na-enyekwa aka kwalite nguzogide corrosion nke ọla kọpa emechara/ọlaakụkụ.N'oge usoro polishing electrolytic, a ga-ewepụ obere oyi akwa nke ihe dị n'elu akụkụ ọla kọpa. Obosara nke ihe a na-abụkarị n'etiti 0.0025 millimeters na 0.063 millimeters, na nke a post-ọgwụgwọ usoro na-enyere aka ime ka elu nke okokụre ọla kọpa./ọlaakụkụ dị nro ma na-egbukepụ egbukepụ, dị ka plating nickel.

2. Electrolating

Electroplating na-enyere aka ịgbatị ndụ ọrụ nke ọla kọpa/ọlaakụkụ, na electroplating ọla kọpa na-enyere aka n'ihu chebe elu elu nke ọla kọpa akụkụ si ọxịdashọn, na-emeso ha na-enweghị imebi conductivity na thermal conductivity nke metal.

3. Ịgba aja

Usoro nhazi nke a na-enye aka na-ekpuchi ntụpọ na ọla kọpa/ọlaakụkụ. Tụkwasị na nke ahụ, ájá ájá nwere ike ime ka elu ahụ dịkwuo ogologo, matte, na nke siri ike.

Oge nzipu: Dec-06-2023